Proven high levels of liberation

As part of our research and development activities, we commissioned geometallurgical and ore mineralogical studies at Martin Luther University Halle-Wittenberg. These studies were carried out under the supervision and guidance of Gregor Borg, who is a full university professor and leads the Economic Geology and Petrology Research Unit. Gregor Borg works also as an internationally known consultant with more than 30 years of experience in mineral resources exploration and recovery and has been contracted by a large number of international exploration and mining companies.

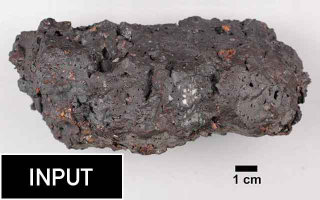

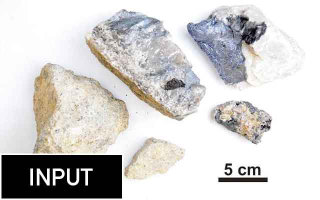

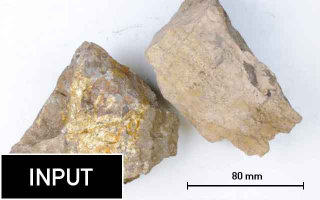

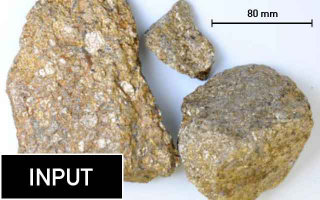

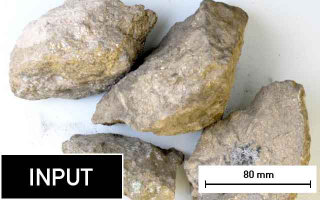

Feed material such as ores and slags, as well as comminution products were characterised granulometrically and analysed by a wide range of up-to-date mineralogical and geochemical methods such as MLA-AMICS, SEM, pXRF, ICP-MS, ICP-AES, and XRD. Amongst other results, the investigations by mineral liberation analyses (MLA) and automated particle recognition (AMICS) revealed the very high levels of particle liberation, which are a characteristic feature of all VeRoLiberator® products.

Take a look at detailed research results from studied bulk samples of ores and slags here.

We tested bulk samples from all around the world

The materials were thoroughly analysed in a standardised process (sieve analyses according to DIN 66165, light-microscopic and scanning-electron-microscopic analyses of both input and output materials, quantitative chemical analyses of all sieve fractions (using a mobile XRF scanner). The results were assembled and interpreted in standardised factsheets. Here we display only summaries of the main results. More detailed factsheets with comprehensive results and data are available on request.

More test results coming soon.

An Understanding how it works

Following the discovery that the VeRoLiberator® achieves such stunning results, we wanted to understand the “how” and the “why”. The rock mechanics specialist at Martin Luther University, Christoph Lempp, Professor of Rock Mechanics and Engineering Geology joined the team and together we developed our current understanding of the working principle of high-velocity comminution by VeRoLiberator®.